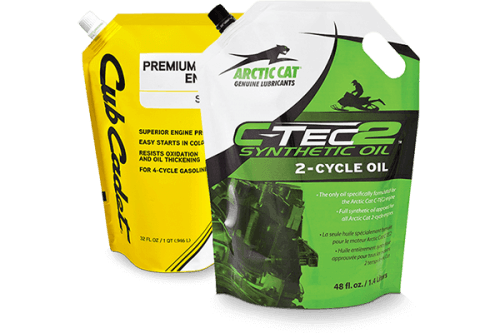

Oil & Lubricants Flexible Packaging

When converting from rigid bottles to stand-up pouches, leading oil & lubricant brands turn to Glenroy. In fact, we helped to develop the first stand-up oil pouch in the U.S. power sports industry, and we’ve helped brands repackage entire product lines of engine oils into stand-up pouches.

When you choose Glenroy for your pouches, our packaging engineers will work with you to understand which features you’d like to incorporate into your packaging, and turn your ideas into prototypes. Our packaging experts also offer on-site technical support, and provide various services such as drop testing, burst testing, and product/package compatibility testing.

Stand-up pouches offer many benefits for oil & lubricant packaging:

Exceptional Convenience and Portability

Stand-up pouches can incorporate convenient features such as spouts and handles to facilitate easy pouring. Pouches also provide the benefit of much lighter package weights, since pouches often use approximately 60 percent less plastic than traditional rigid bottles.

Shelf Impact

Stand-up pouches stand out amongst the rows of bottles currently on shelves, providing you with an additional competitive advantage. Flexible packaging offers a way for oil and lubricant manufacturers to differentiate their products, and stand-up pouches provide approximately 7 times more printed surface area to display eye-catching graphics than what is provided by labels on bottles.

View an interactive 360° view of a stand-up oil pouch with tamper-evident easy-pour spout and ergonomic angled handle:

First Stand-up Oil Pouch in U.S. Power Sports Industry

Discover how Arctic Cat committed to flexible pouches for a new 1.4-L container of engine oil.

Durability and Protection

We custom-engineer stand-up pouches that are extremely durable. Pouches must provide excellent seal strength in order to withstand rigorous burst testing and drop testing, and we have experience in engineering pouches with extremely high seal strength.

Advanced Barrier Materials

When choosing flexible packaging, protecting the integrity of high-performance oils and lubricants can present a challenge for other flexible packaging suppliers because oil can migrate through many flexible packaging structures. When oil attacks and migrates through materials, this creates an issue called “delamination”—which comprises the integrity of the product and the strength of the pouch.

At Glenroy, we have decades of experience packaging specialty lubricants and oils, and we take the time to do product/package compatibility testing to account for the unique formulation of each oil or lubricant. Our highly engineered flexible packaging materials provide unique barrier properties that protect the integrity of high-performance engine oils, lubricants, and fuel additives.

Eco-friendly Packaging

Pouches also provides several environmental benefits. As compared to a rigid plastic oil bottle, a flexible pouch:

- Requires less energy and generates less CO2 emissions during production.

- Results in a higher product-to-package ratio.

- Requires fewer trucks for transportation, reducing fossil fuel consumption and CO2 emissions.

- Produces significantly less landfill waste through source reduction.

Additional Benefits

Compared to rigid bottles, inventories of spouted pouches are much more space efficient and requiring much less area to store.

Project a brand image of innovation, environmental awareness, and quality by choosing stand-up pouches.