Stand-up pouches are one of the fastest growing packaging formats, with stand-up pouch usage projected to grow by 7% each year through 2018. Thanks to advances in flexible packaging materials, fitments, and filling equipment, many products once limited to rigid packaging are now excellent candidates for pouches.

When thinking about packaging for liquid products, pouches may not be the first thing that comes to mind. But an increasing number of brands are switching from rigid packaging to stand-up pouches for liquid products such as beverages, syrups, cleaning solutions, and even oils and lubricants.

Why Convert from Rigid Packaging to Pouches?

The benefits of choosing stand-up pouches over rigid packaging are many. Flexible pouches:

- Are conveniently lighter and more portable for today’s on-the-go consumers.

- Result in a higher product-to-package ratio.

- Use approximately 60 percent less plastic than rigid plastic bottles.

- Allow for more efficient warehousing since unfilled pouches take up significantly less space than rigid packaging.

- Allow for near total evacuation of the product. (Rigid containers can leave 6 – 14% of product in packaging, while pouches can evacuate up to 99.5% of the product.)

- Require approximately 50 percent less energy to produce.

- Generate less CO2 emissions during production.

- Produce less landfill waste.

- Require fewer trucks for transportation—reducing fossil fuel consumption and CO2 emissions.

- Provide shelf impact, differentiation, visibility, and a wide range of convenient features that all translate to a competitive advantage for your brand.

For example, in 2013, we produced a durable spouted stand-up pouch for Arctic Cat’s innovative C-TEC2 Synthetic engine oil. It was the first oil pouch in the U.S. power sports industry. Not only did the new pouch provide the benefits listed above, but converting from the industry standard 32 oz. F-style quart bottle to a pouch also:

For example, in 2013, we produced a durable spouted stand-up pouch for Arctic Cat’s innovative C-TEC2 Synthetic engine oil. It was the first oil pouch in the U.S. power sports industry. Not only did the new pouch provide the benefits listed above, but converting from the industry standard 32 oz. F-style quart bottle to a pouch also:

- provided a sizeable increase (over 500%) in printable surface area to present attention-grabbing graphics and key information.

- facilitated easier dispensing of oil into compact oil reservoirs.

- reinforced the high-performance, environmentally-conscious characteristics of the brand.

While many companies can supply pouches, when seeking stand-up pouches for liquid products, it can be beneficial to seek out a pouch supplier with additional specialized expertise in the area of designing packaging for liquids. There are several potential pitfalls that can be encountered when producing pouches for liquids, and a supplier with experience in working with liquids will know how to navigate around these obstacles.

1. Pouch Converting

Some suppliers with experience in engineering and manufacturing stand-up pouches for liquids have developed techniques for pouch converting that provide safeguards against potential leaks. According to Kevin Riggs, pouching operations manager here at Glenroy Inc., “We use methods of pouch sealing that create stronger seals and help to prevent leaks in the most vulnerable areas of a pouch. These methods aren’t used across the board by all pouch converters. We’ve developed these methods through experience and by working closely with pouch machinery manufacturers.”

2. Pouch Prototyping

Certain pouch shapes encourage buckling or folding of the flexible packaging film, which can lead to stress fractures—and ultimately leaks. And liquid pouches that are too large for one-handed dispensing usually require a die-cut handle to provide two points of contact for the consumer to use when pouring.

A pouch supplier with experience in liquid pouches can collaborate with you to create innovative pouch prototypes that prevent stress fractures and provide structural stability, shelf impact, convenience, and ease-of-use. (Advanced pouch suppliers can even supply pouch prototypes printed with your products’ graphics.)

3. Filling Equipment

When designing prototypes, your pouch supplier should also know and take into account the filling process that is going to be used for your pouches. For example, certain pouch filling equipment may require extra area on pouches to account for the sealing bar. The filling process is a critical aspect in the supply chain and often impacts pouch design. Producing a pouch without taking into consideration the filling equipment is a recipe for disaster.

4. Flexible Packaging Materials

The flexible packaging structure chosen for your pouches plays an essential role in preventing pouch failures. As background information, a flexible packaging structure typically consists of multiple layers of materials laminated together, with each layer performing a crucial role in the performance of the package.

The flexible packaging structure chosen for your pouches plays an essential role in preventing pouch failures. As background information, a flexible packaging structure typically consists of multiple layers of materials laminated together, with each layer performing a crucial role in the performance of the package.

Puncture resistance and durability are extremely important when designing pouches for liquids, and certain flexible packaging materials are ideal for puncture resistance and durability. An experienced pouch supplier will incorporate these materials into the flexible packaging structure engineered for your pouches.

Be wary of any pouch supplier that offers a standard “menu” of flexible packaging materials. Choosing a pouch supplier who can engineer customized flexible packaging laminations based on your products’ unique formulations can aid in preventing product/package compatibility issues once your products are in the hands of your consumers.

5. Pouch Testing

When designing and manufacturing pouches for liquids, testing is yet another key to preventing pouch failures and ensuring that your pouches will perform throughout the life cycle of your products.

Throughout the stages of package engineering, packaging film manufacturing, and pouch converting, your pouch supplier should subject your pouches to various types of testing, which may include:

Throughout the stages of package engineering, packaging film manufacturing, and pouch converting, your pouch supplier should subject your pouches to various types of testing, which may include:

- product/package compatibility testing

- compression testing

- seal testing

- puncture resistance testing

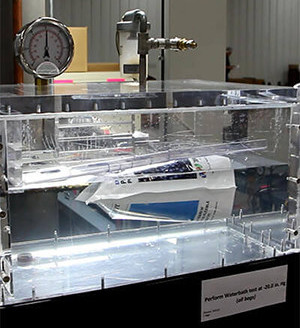

- water bath testing

- tensile testing

- burst testing

- drop testing

Each type of testing plays a critical role in ensuring that the final package will function optimally. For example, when forming pouches, frequently performing water bath testing (a test using external pressure) and internal pressure testing throughout each pouch converting run can immediately detect any leaks or weak seals.

6. Spouts and Fitments

Spouts and fitments play an essential role in the functionality of pouches for liquids. According to Dave Johnson, food market strategic business development manager at AptarGroup, “A key component to the popularity of stand-up pouches is the continued evolution of spouts and fitments.”

A wide variety of innovative spouts & fitments are available to add convenient features to pouches, such as easy opening and reclosing, audible feedback, tamper evidence, child safety, one-handed dispensing, clean product cut off, and controlled pouring. Some spouts & fitments are designed for solids & particulates, while others are ideal for liquids.

A pouch supplier with experience designing spouted pouches for liquids can guide you towards spout & fitment options that are optimal for your products’ viscosity and improve the consumer experience. For example, AptarGroup’s SimpliSqueeze® valve technology is available within several of AptarGroup’s fitments designed for liquids. The SimpliSqueeze® valve prevents leaks, controls the volume and stream of a liquid as it is dispensed from a pouch, and provides superior product cut off—providing mess-free dispensing. SimpliSqueeze® valve technology has been used in rigid packaging closures for over fifteen years, and is now available within several of AptarGroup’s spouts for flexible packaging.

SimpliSqueeze® valves are available in various slit configurations, diameters, and shapes. Smaller valves are especially suited for dispensing products with thinner viscosity, while larger valves are best for dispensing thicker-viscosity products like spreads—such as jellies, sour cream, etc. The size of the valve slit should be chosen based on the volume of product dispensed with each use, how much force the consumer applies to the pouch when dispensing the product (ease of squeeze), and the characteristics of the desired product stream.

Thinking Outside the Bottle

There is a misconception about flexible packaging that is becoming less prevalent, but still exists for some. That misconception is the belief that pouches aren’t as durable or functional as rigid packaging. According to Evan Arnold, product development manager here at Glenroy Inc., “I think the biggest struggle for liquid pouches is overcoming the misconception that they can’t perform the same functions as a bottle. When designing pouches for liquids, we as packaging engineers need to understand the various ways that choosing flexible packaging can improve a package’s functionality or solve a problem, and add value for the consumer. There are many ways pouches can add convenience and improve the consumer experience.”

When addressing the perceived durability of pouches, Riggs points out, “We’ve developed spouted pouches that hold 32 oz. of liquid and pass 12 ft. drop testing. In my opinion, pouches can perform as good, and in some cases better, than bottles.” Any remaining misconceptions about the durability of pouches will likely subside as numerous liquid products migrate from rigid packaging to pouches, and the “flexible packaging natives”—a generation of consumers that grew up drinking juice from flexible pouches—take center stage.