Custom Engineered Laminations

Custom Engineered Laminations

While some flexible packaging manufacturers offer a standard “menu” of flexible packaging materials, at Glenroy, we engineer customized flexible packaging structures designed specifically for your products.

We’ve specialized in flexible packaging since 1965, and our expertise in polymer chemistry and flexible packaging engineering allows us to design optimal, cost-effective flexible packaging materials. We work with a vast range of films, foils, papers, and resins when engineering customized flexible packaging laminations.

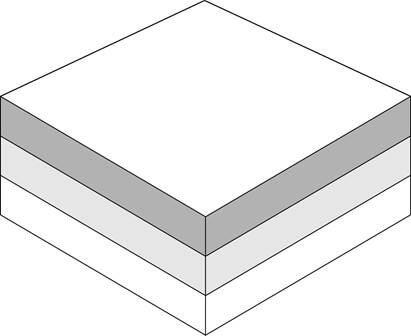

A flexible packaging structure typically consists of multiple layers of materials laminated together, with each layer performing a crucial role in your packaging’s performance and presentation.

Each layer provides specific performance characteristics, such as:

- Oxygen, moisture, or light resistance

- Chemical resistance

- Puncture resistance

- Tear resistance

- Rigidity

- Glossy or matte appearance

- Opacity or translucency

- Heat sealability

- Print receptivity

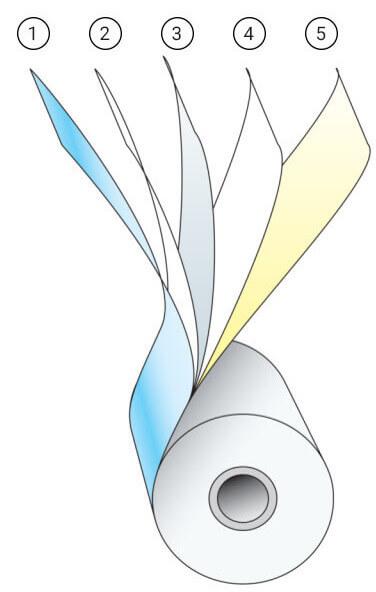

The example below shows the duties each layer performs within a basic five-layer extrusion laminated flexible packaging structure:

1. Exterior Layer

- Provides dimensionally-stable print surface

- Protects the ink

- Protects the barrier layer

- Plays a role in burst strength & tear resistance

- Adds to overall pouch strength

2. Tie Layer

- Provides another layer of protection for the barrier layer

- Bonds the outside layer to the barrier layer

- Hides the color of the barrier layer

3. Barrier layer

- Provides chemical resistance

- Prevents moisture, light, and oxygen transmission

4. Tie Layer

- Bonds the barrier layer to the sealant layer film

- Provides protection for the barrier layer

5. Sealant Layer

- Allows the flexible packaging structure to be heat-sealable

- Provides burst strength

- Seals the product within

- Protects the barrier layer

Based on your requirements (including regulatory, cost, and aesthetic requirements), packaging equipment, product formulation, projected life cycle, and distribution methods, we can custom-engineer and suggest optimal flexible packaging structures for each of your products.